The Siskiyou line: Track quality

The best example for fixed plant maintenance in Southern Pacific's very last decades might be "Tunnel No. 1". A tree was allowed to grow on top of the tunnel for nearly 100 years, until finally, it got big enough to break through the tunnel ceiling with its roots. Instead of repairing the damage, SP built a passing loop, using a radius of 383 feet. Such curvature hadn't been acceptable for cheap engineering of 1881.

The tightest curve of the Shasta route is a result of Southern Pacific's fixed plant maintenance.

Southern Pacific used to be an icon of wealth and power. The last decades of its existence were different: The company couldn't maintain its rolling stock properly, and its fixed plant slowly degraded in quality. The Siskiyou line was no vital part of the SP network, and was treated worse than the neglected trunk routes.

Today's operator, "Central Oregon & Pacific", has invested within those limits, that fit to the operation of one freight per direction per workday. In the given situation, replacing 10 mph slow orders with class 2 track will have had the highest priority. This allows 25 mph for freight.

The speed of a successful passenger service is out of reach on the existing track. It's not even guaranteed, that the timetable of 1927 would be achievable. Without accepting the precondition, that the track needs a major maintenance of way effort, thinking a single thought about passenger traffic is a waste of time.

Track alignment problems are visible to the bare eye.

For higher speeds, railroad track needs to be aligned more precisely, with the acceptable tolerances declining faster, than the speed rises. It is no technical problem, to lay down track, that keeps precise alignment for several years, but the following problems need to be avoided:

- If the ballast has collected more than 30% dirt, it will no longer provide a precise roadbed. Maintenance intervals get shorter and shorter with further buildup of dirt in the ballast.

- If the subgrade does not provide proper drainage, the track will be pushed out of alignment by frost heaves.

- If the subgrade has soft spots, ballast will disappear into the subgrade.

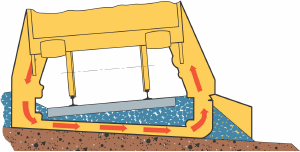

With today's technology, these problems are fixed by the application of a single machine. It takes out the ballast, takes out the top of the subgrade, levels the subgrade to the proper drainage angle of 20 - 25°, applies a fabric on top, adds a thin subgrade protection layer made out of wetted sand and fine gravel, compacts this to high density, sharpens and filters the old ballast, washes the ballast, and puts the old ballast back on the track, plus minor amounts of new one. Progress of such machinery is about 200 feet per hour.

The excavator chain can install the subgrade drainage angle independent of superelevation.

In the old days, this kind of strengthening and drainage repair used to need

- removal of track and subgrade.

- access roads for construction machines and trucks.

- depots, storage places, and processing plants for sand and gravel.

- lots of transport.

Today, the same work is done highly automated, required infrastructure is the track itself, no truck needs to get in sight. Most of the necesssary material transport is done by conveyor belts within the train, due to the high percentage of recycled material. It's much faster, and cost savings are huge, especially for track like the Siskiyou line, that is accessible only by rail at several locations. Nonetheless, 300 miles mean a considerable investment, and the Siskiyou line needs new rails and ties as well. This replacement can be done in combination with the subgrade and ballast improvement.